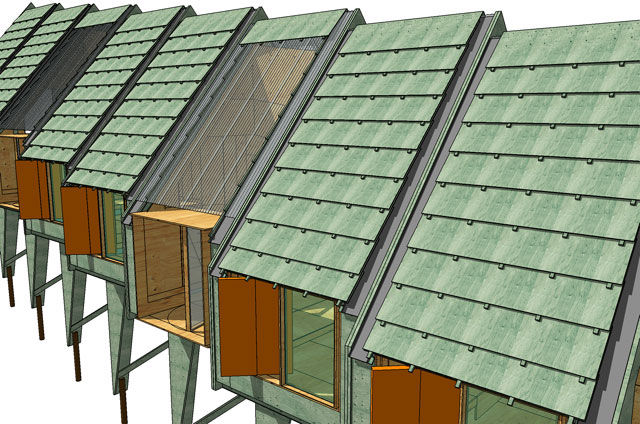

external perspective

service/entrance module (type B)

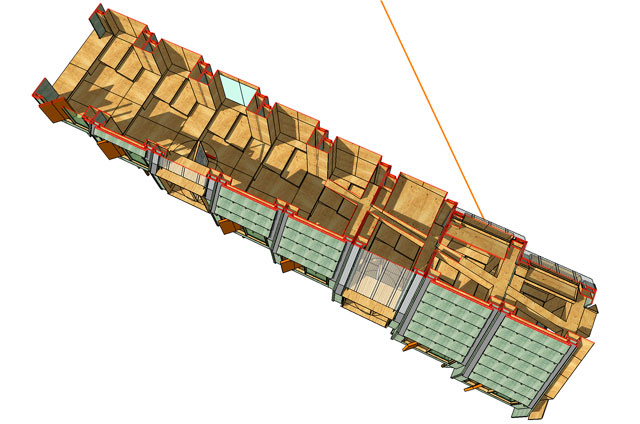

cut away plan

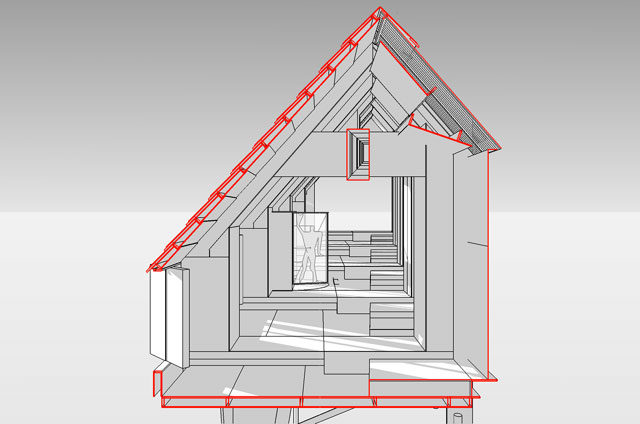

cross-section showing Structural Insulated Shingles and central air handling spine

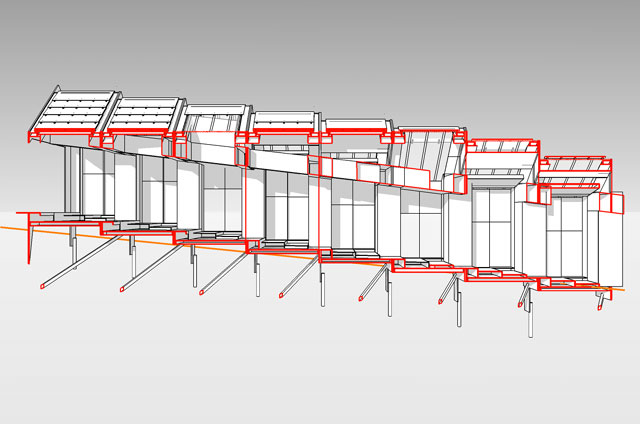

long-section (showing blanks-only for the northern wall)

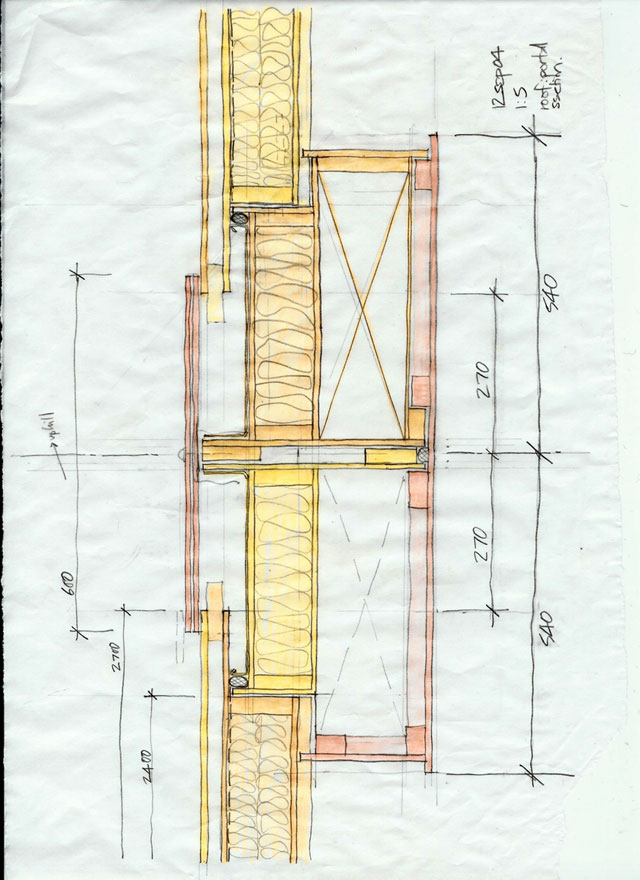

typical portal mating junction: some thicknesses are wonky

Since then my garden sketching has produced a variation of the above – more monocoque like, and using far less material. I still need to model it, though…

This is where we stand with the design:

The form of the building takes its primary cues from:

- the terrain (we do not want to excavate, which is a big ask on a 40° slope )

- planning constraints (prescribed site shadow angles define a narrow, “steeply roofed” corridor of space through the site).

- economy: the strictly modular all-plywood componentry exploits commercial board sizes and allows accuracy and efficiency through being prefabbed offsite. A considerate aspect of this approach is that we can build as many as we can afford (the design shows the maximum number that you can fit on the site in a single trajectory – bringing a square meter-age of around 120m2 excluding all the plug-in module bits (see previous post)).

- thermal performance: Each service module traps whatever sun energy we can via its glazed roof and stores it in a thermal mass unit (effectively a bunch of heavily insulated water bottles high up in the roofspace). Fresh air is drawn in from the surrounding service module space. A heat-exchanger allows us to control how much fresh/cool air we mix into the system to keep things comfortable.

We distribute the warmed air via inline fans (controlled wirelessly via simple software routines which I’ll write using AppleScript) using the central duct system – we can feed heated fresh air to where its needed: below windows and along bench-seats etc. From there it’ll simply rise up into the roofspace, bumping along the portals until it re-enters the service module etc etc.We can introduce heat through underfloor electric panels for times when the sun is blatzoed. I’m worried about the amount of noise such a system will make.

I was originally thinking of each service module as being glazed off from the rest of the house (for thermal performance), but lately I’ve started to consider long, theatre-thickness drapes or industrial felt hanging in curtains of battens… - natural lighting: glare is a big problem in Wellington, and when you want to suck in as much sunlight as possible and at the same time make the most of the views, you hit a problem. We’ll be directing most northerly windows directly into the slope (jungle-like, not much light), with loads of northerly light coming in via the rooflight strip, but with the glare moderated by being sprayed up into the roofspace via the tilting lightshelf device. The windows towards the view are mostly southerly, and we can afford to bang them up into large, exposed windows (double glazed, fixed, low-e yadda yadda).

- flexibility: within reason we can swap and change how we want to use the structure: maybe we want to use the lower part of the house for workshops etc where we can fling paint around and weld / saw / create away to our hearts content.

So far all doors are simple centrally-pivoting numbers: you can easily create a variable opening size and (almost) not worry about the thing slamming open or shut in the wind.

An accurate site survey shows that we can lift the structure up off the ground (to gain more morning winter sun) before we hit the shadow plane constraint. Accordingly the substructure has required more beef than I first thought… where is my structural engineer?